Single-Chamber Ultimate Vacuum-Sealed Cleaning System “F1 Clean”

“F1 Clean” is your choice if you choose between washing cost and work environment.

Ultra-low consumption of solvent has realized significant reductions in washing cost.

It meets customers’ diverse requirements as to work piece sizes and volumes to be treated, as well as automated operation.

Single chamber capable of washing, rinsing and drying

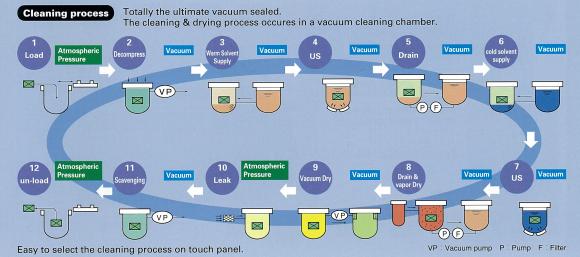

[Chart] (1) Loading [Washing chamber internal pressure / Atmosphere]

(2) Decomperss [Vacuum] (3) Warm solvent supply [Vacuum]

(4) Ultrasonic washing [Vacuum] (5) Drain [Vacuum]

(6) Cold solvent supply [Vacuum] (7) Ultrasonic washing [Vacuum]

(8) Clean vapor drying [Vacuum] (9) Vacuum drying [Vacuum]

(10) Aeration [Vacuum] (11) Scavenging [Atmosphere] (11) Un-Loding

Our original sealed structure (PAT) realizes ultra-low solvent consumption.

Our original sealed structure (PAT) realizes ultra-low solvent consumption.

Have you noticed a decrease of solvents while the equipment is not being operated?

The AQMD (Air Quality Management District) of the United States, which is known to be the strictest concerning air pollution, highly evaluated PAT’s sealing performance and safety, and recognized our “F1 Clean” as a sealed solvent washer accredited to its standards.

Using our patented system, “F1 Clean” significantly reduces running costs of costly solvents.

It also realizes an optimum work environment that places virtually no load on the operator.

Safety-assured sales performance

Since the use of fluorocarbon was prohibited, our F1 Clean system has enjoyed overwhelming support and patronage of numerous customers.

Can be installed in clean rooms

Since the whole of F1 Clean is a sealed structure, it never pollutes the clean room environment.

Washing chamber most suitable for precision washing

The washing chamber is bowl-shaped with a mirror polished inner surface and hard chrome plate making it possible to remove particles smoothly.

All solvent to be supplied into the washing chamber is filtered.

Since vapor is supplied from a dedicated vapor generator, vapor washing cleaner unlike that of open-type washers, with which vapor washing is carried out over the distilling chamber, is available.

Work environment improvement

The low washing chamber table height of 910mm (H) means excellent work efficiency.

Extremely easy to operate – you simply push the start switch.

(The same washing quality is available even when operators have changed.)